XA 120/250.5Y Analytical Balance

Why Are the XA 5Y Balances Worthy of Consideration?

Semi-automatic levelling – LevelSENSING System

Manually opened weighing chamber

Internal adjustment

Digital Weighing Auditor

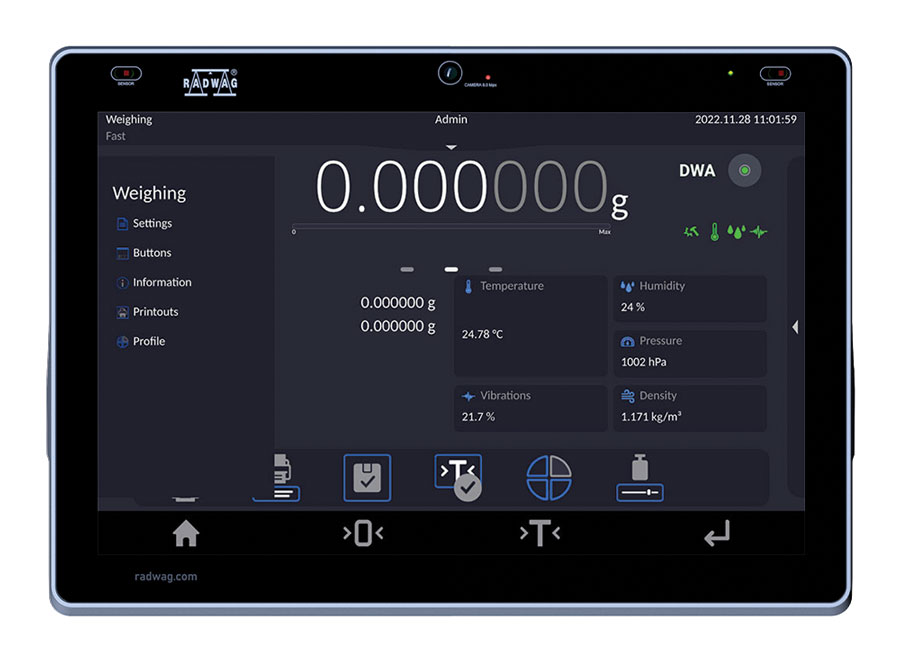

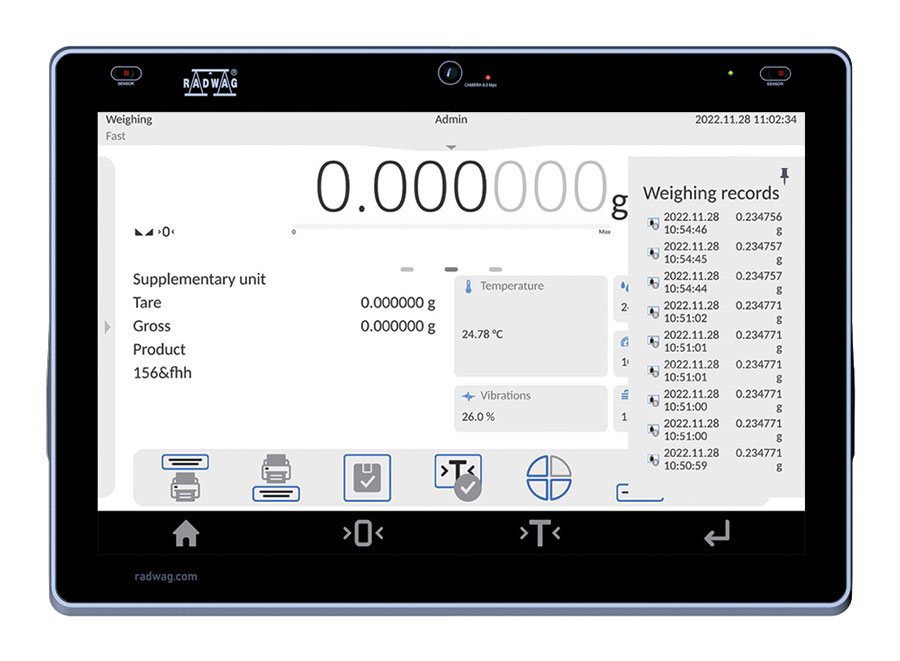

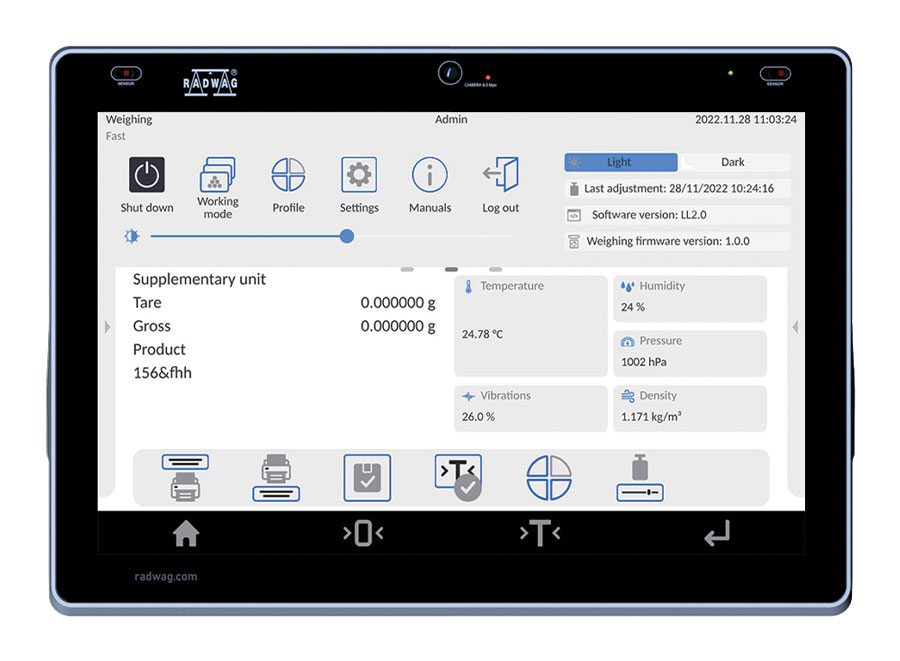

10-Inch Display

Uncompromising User Verification

Ambient Light – one look and everything is clear

Hotspot

RFID

Live Note – Note Down Your Conclusions

Handy Library

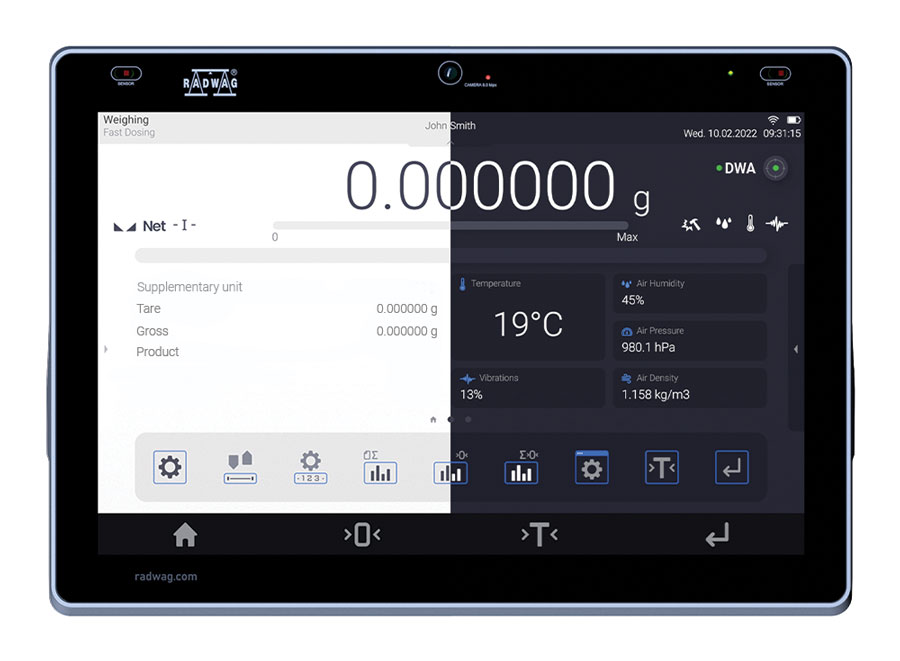

Widgets

Smart Min Weight

21 CFR Part 11

– Full data security

– Validations

– Electronic records

– Audit trails

Additional fee

Additional fee

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Português (Brasil)

Português (Brasil) Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano Japanese (日本語)

Japanese (日本語) Polski

Polski Türkiye

Türkiye Česky

Česky 中文

中文