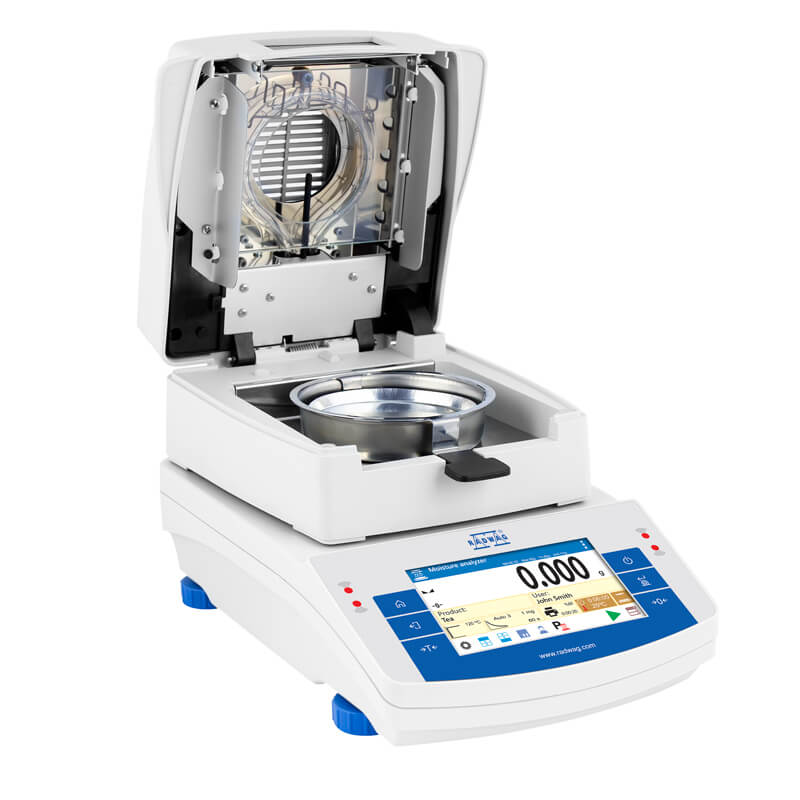

MA 210.X2.IC.A.WH Moisture Analyzer

MA.X2.IC.A series

- Maintaining moisture analyzer clean – operator does not touch moisture analyzer’s housing.

- Removing any shocks caused by manual closing of the chamber – the chamber closes automatically and always with the same intensity.

- Achieving high repeatability of opening and closing the drying chamber.

- Enhancing drying process automation.

- Enhancing safety of operation by eliminating contact with hot components of drying chamber.

- Improving operation ergonomics.

MA.X2.IC.A series features user-friendly colour touchscreen. Free configuration of the control panel can be done by means of hotkeys, customizable information fields and programmable labels. Drying process can be carried out for any temperature and – thanks to databases – particular drying process may be set for a specific product.

Highlights of X2 Series moisture analyzers:

- Automatic opening and closing of the drying chamber

- 5” capacitive colour touchpad

- Modern interface

- Uncomplicated, intuitive operation

- Programmable display

- Drying profiles (standard, mild, step, fast)

- GLP/GMP printouts-reports

- Repeatable and customized applications

- Work optimization due to the use of halogen lamps

Capacity and

temperature

An additional element for moisture analyzers that improves their functionality is a water vapour permeability determination set used in tanning industry for determining hygienic properties of leather.

Databases

Collected data is registered in 8 databases:

- Products (5 000 products)

- Users (100 users)

- Packaging (100 packaging types)

- Customers (1 000 customers)

- Drying programs (200 drying programs)

- Drying process reports (10 000 drying process reports)

- Ambient conditions (10 000 records)

- Weighings (50 000 records).

The results

- % M – the mass loss in %; displays the mass change recorded during the drying process, expressed as a percentage,

- % D – the dry mass obtained during the drying process, expressed as a percentage; the result is the portion of the sample that remains on the weighing pan after the moisture has evaporated,

- % R – the ratio of moisture content to dry mass, obtained during the drying process, expressed as a percentage; the result is the portion of the sample that evaporated during the drying process,

- g – the sample mass after drying.

Interfaces

Remote access to the moisture analyzer allows for online data management.

Cooperation with E2R allows for external data management which in turn increases the efficiency and results to the maximum.

Learn about the use and maintenance of stainless steel products:

Stainless Steel in RADWAG products. Standard and special applications

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Português (Brasil)

Português (Brasil) Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano Japanese (日本語)

Japanese (日本語) Polski

Polski Türkiye

Türkiye Česky

Česky 中文

中文