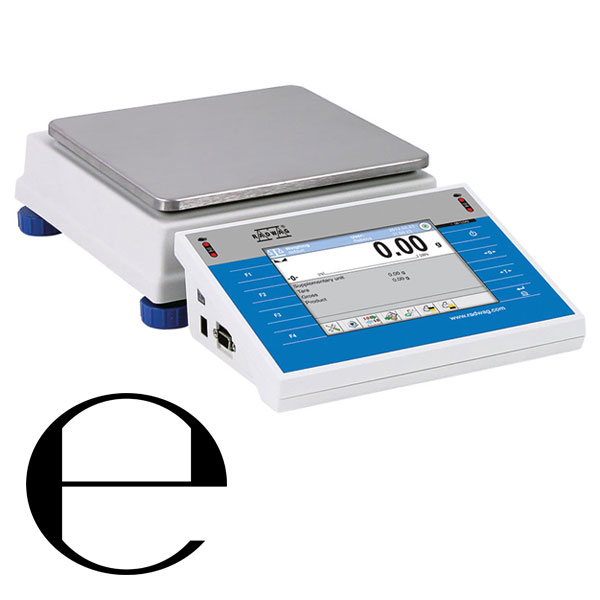

Balance WLY pour contrôle statistique

Boîter et fonctionnalité

- programmation des touches d’écran

- programmation des touches fonctionnelles

- programmation des senseurs du mouvement

- élaboration des modèles des impressions

- élaboration des informations de texte dans la fenêtre de l’afficheur de la balance.

Les balances sont vérifiées en deux étapes. En égard à l’accélération normale de la pesanteur terrestre, le calibrage de la balance est nécessaire dans le lieu de son exploitation.

Les étapes du contrôle:

- choix de l’opérateur

- choix du produit

- commencement du contrôle

- téléchargement des pesages

- fin automatique du contrôle après le pesage du nombre déterminé des colis

- impression du rapport de contrôle

Par conséquent, nous vous recommandons de choisir les balances avec une homologation respective.

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Português (Brasil)

Português (Brasil) Deutsch

Deutsch English

English Español

Español Italiano

Italiano Japanese (日本語)

Japanese (日本語) Polski

Polski Türkiye

Türkiye Česky

Česky 中文

中文