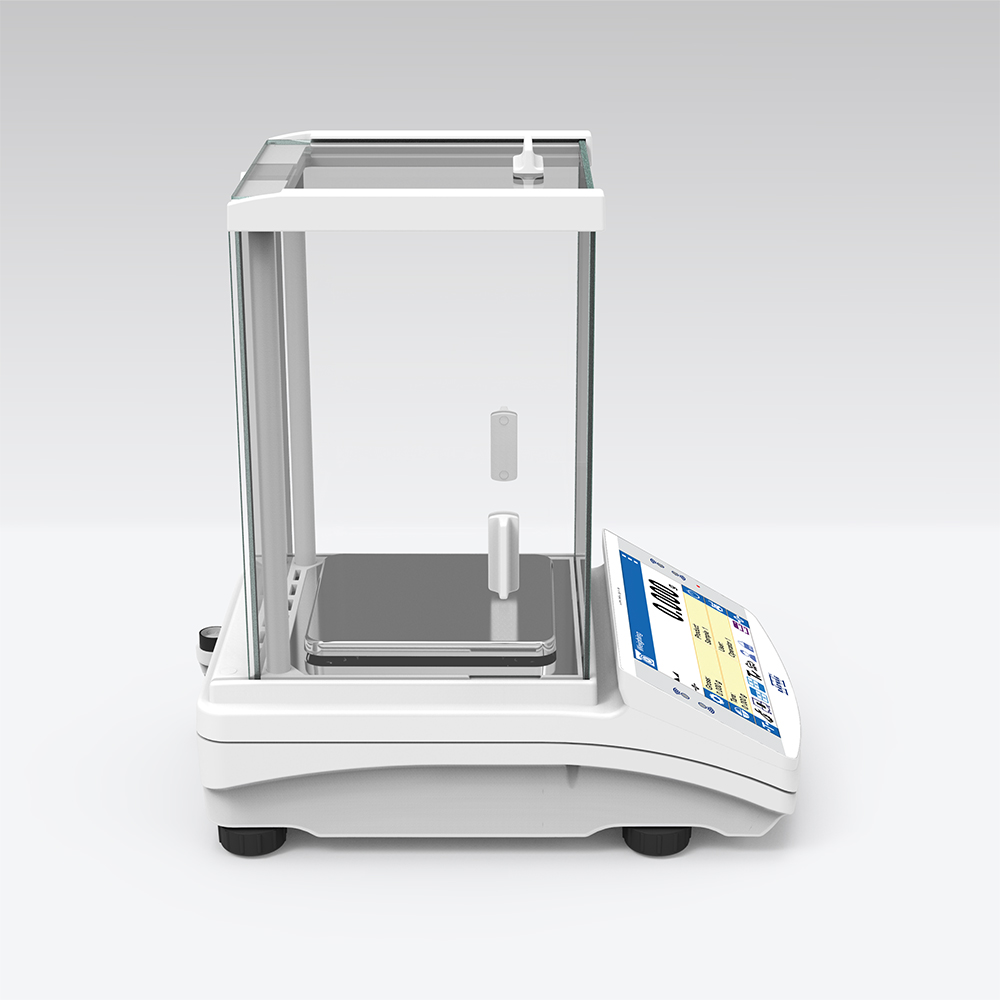

Präzisionswaage PS 750.X7.FPVO

Wir empfehlen die Bestellung einer Waage mit entsprechender Eichung.

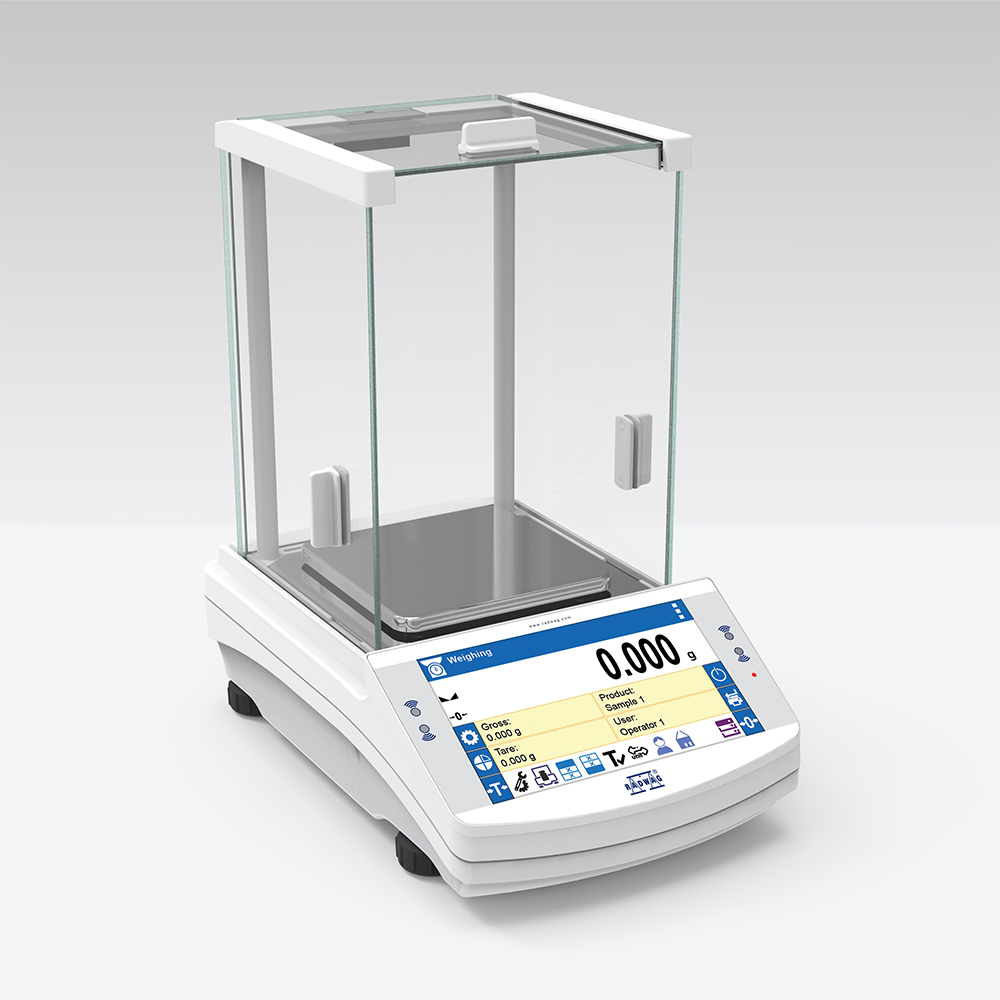

Präzisionswaagen PS X7

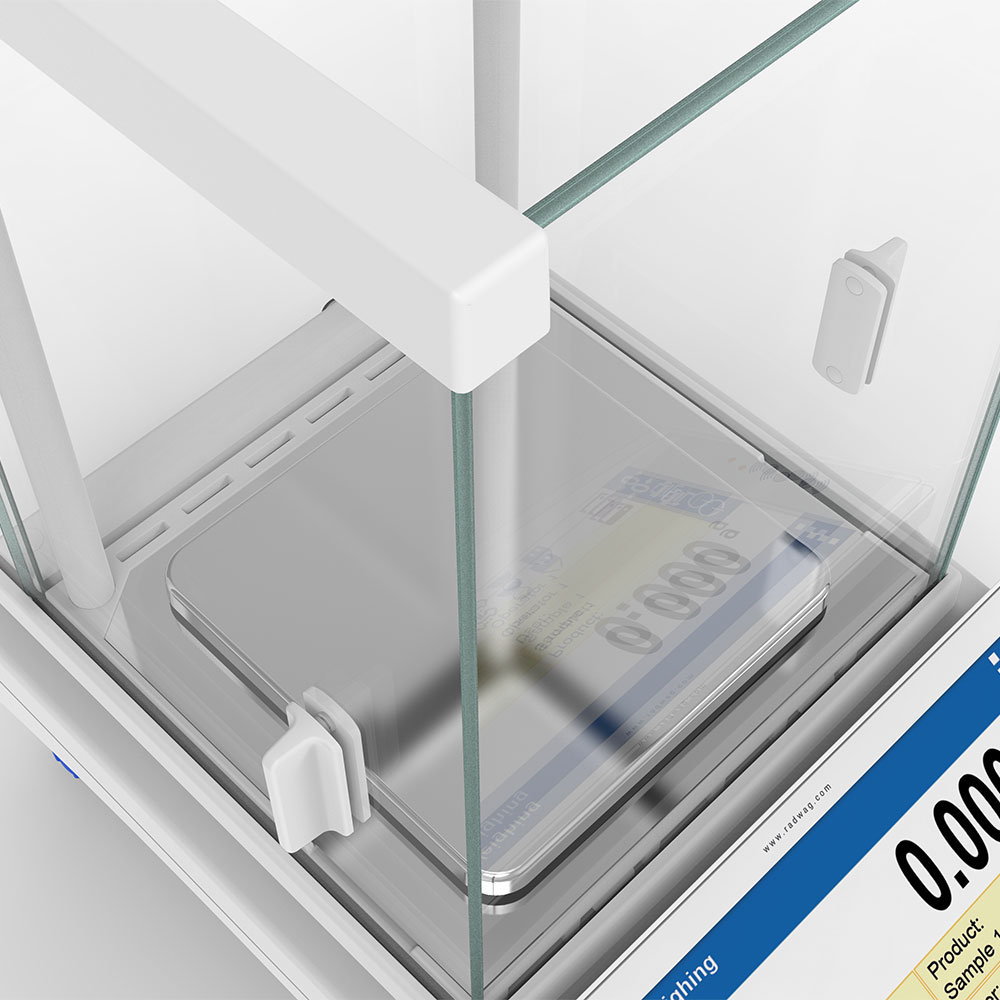

Die PS X7-Waagen sind mit zwei Infrarotsensoren ausgestattet, die eine berührungslose Bedienung ermöglichen.

Neue Möglichkeiten

Die Präzisionswaagen PS X7 sind mit mehreren Kommunikationsschnittstellen ausgestattet: 2 x RS232, USB-A, USB-B, Ethernet und Wi-Fi. Das Gehäuse der Waagen ist aus Kunststoff und die Waagschale aus Edelstahl gefertigt.

Datenbanken

Die Daten werden in 11 Datenbanken gespeichert:

- Produkte (5.000 Produkte)

- Benutzer (100 Benutzer)

- Verpackungen (100 Verpackungen)

- Kunden (1.000 Kunden)

- Rezepturen (100 Rezepturen)

- Rezepturberichte (500 Berichte)

- Umgebungsbedingungen (10.000 Datensätze)

- Wägungen (50.000 Datensätze)

- Alibi-Speicher (512.000 Datensätze)

- Kontrollberichte (1.000 Berichte)

- Durchschnittliche Tara (1.000 Berichte).

Datenverwaltung

ALIBI-Speicher

Der ALIBI-Speicher ermöglicht die Speicherung von bis zu 512.000 Wägedaten.

Additional fee

Additional fee

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Português (Brasil)

Português (Brasil) English

English Español

Español Français

Français Italiano

Italiano Japanese (日本語)

Japanese (日本語) Polski

Polski Türkiye

Türkiye Česky

Česky 中文

中文