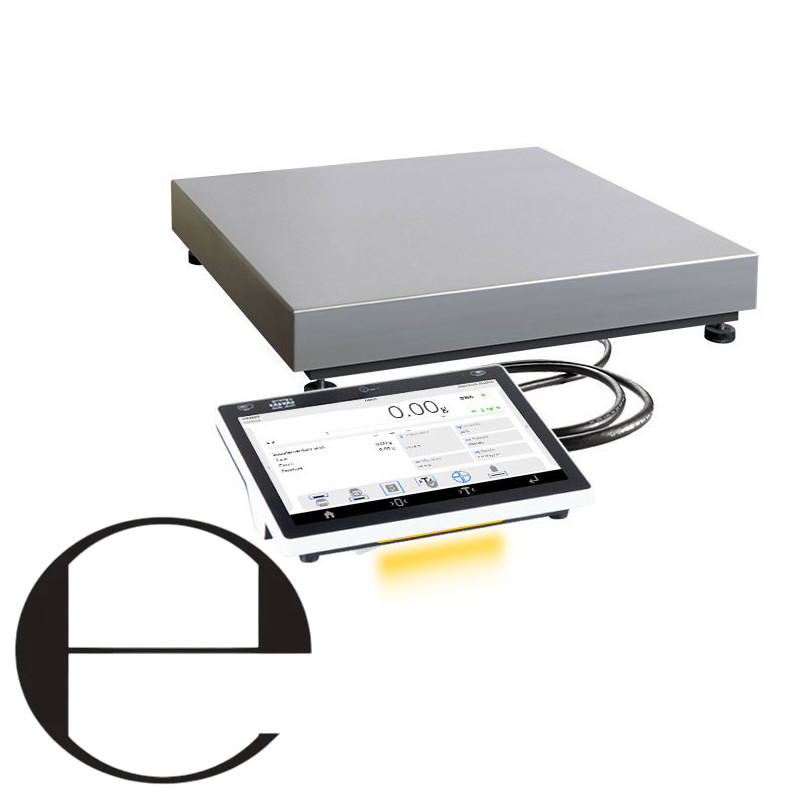

Bilancia per l'ispezione di prodotti confezionati

Progettata per facilitare il vostro lavoro

Scopo: controllo dei prodotti confezionati

Il ciclo di ispezione procede come segue:

- selezione dell'operatore

- selezione della merce

- selezione o controllo della tara

- pesatura

- conclusione automatica con indicazione del risultato del controllo

- salvataggio del rapporto o stampa dello stesso.

Quali sono gli ulteriori vantaggi della bilancia CY10.CPC?

- la programmazione dei tasti a schermo e dei tasti funzione

- la programmazione dei sensori di movimento

- la progettazione di schemi di stampa

- la progettazione di informazioni testuali nella finestra di visualizzazione della bilancia.

Wi-Fi® is a registered trademark of Wi-Fi Alliance®.

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Português (Brasil)

Português (Brasil) Deutsch

Deutsch English

English Español

Español Français

Français Japanese (日本語)

Japanese (日本語) Polski

Polski Türkiye

Türkiye Česky

Česky 中文

中文