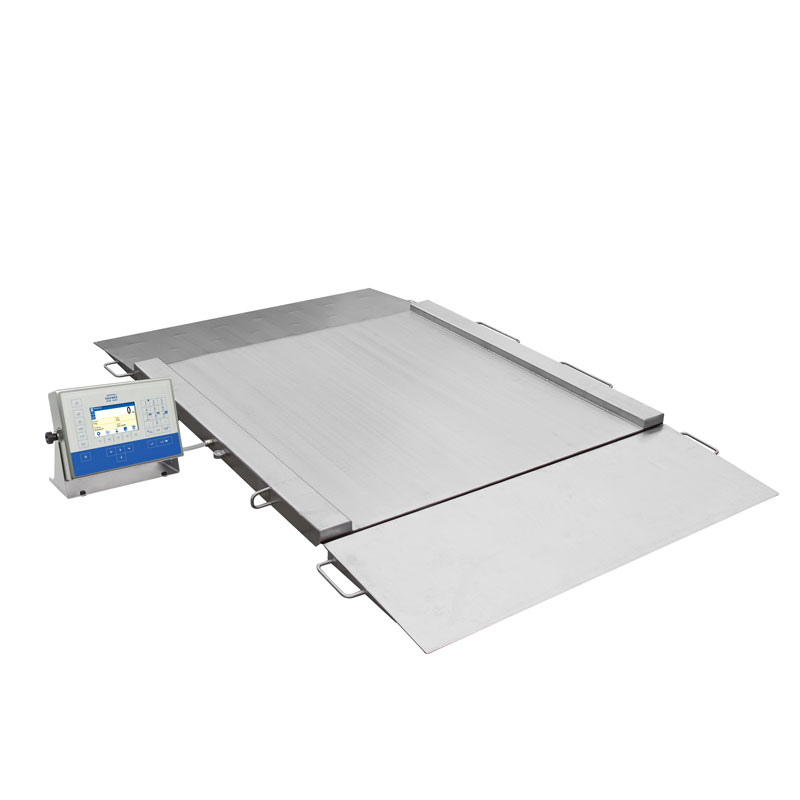

The HX5.EX scale is a modern weighing instrument assuring fast and reliable measurement in hazardous areas classified as zones 1/21 and 2/22. To ensure precision and excellent measurement repeatability, high quality electronic components are used.

The weighing platforms offered in wide range of dimensions and maximum capacities, this combined with excellent metrological parameters enables easy selection of an instrument that meets the most demanding requirements.

Standard version of the scale is equipped with 2 serial, intrinsically safe RS232 communication interfaces, and with one RS485 interface. They facilitate cooperation with equipment intended for operation in hazardous areas. Possibility to add digital inputs/outputs extends the range of instruments compatible with the indicator by automatic elements compliant with ATEX directive.

More demanding customers can use the IM01.EX module, installed in the safe area, which extends the available connectors by Ethernet, USB, 4-20mA/0- 10V analog outputs, Profibus DP and additional digital inputs/outputs. This enables cooperation with external devices: barcode scanners, printers, external displays, control buttons, light signalling towers, other controlling/signalling devices, systems for automatic process control and superior IT systems.

Scale operation requires use of a dedicated PM01.EX power supply, which is not a standard scale component.

To operate the scale, order a selected type of the dedicated intrinsically safe power supply.

Power supply types:

-

PM01.EX-1 - power supply for operation in ATEX area. Used when it is required to connect the power supply to voltage source placed in hazardous area.

-

PM01.EX-2 - power supply for operation outside ATEX area. Used when power supply connection to voltage source is carried out outside hazardous area.

Complex software enables carrying out many tasks connected with mass measurement, e.g. parts counting, checkweighing and statistics.

The scales feature user-friendly graphic interface, which can be customized using widgets. This and the large colour display of high resolution guarantee easy and clear transmission of data on current process.

Colour bar graph significantly influences performance by signalling whether the weighing result is within declared thresholds or not.

Additional fee

Additional fee

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Português (Brasil)

Português (Brasil) Deutsch

Deutsch English

English Español

Español Français

Français Japanese (日本語)

Japanese (日本語) Polski

Polski Türkiye

Türkiye Česky

Česky 中文

中文