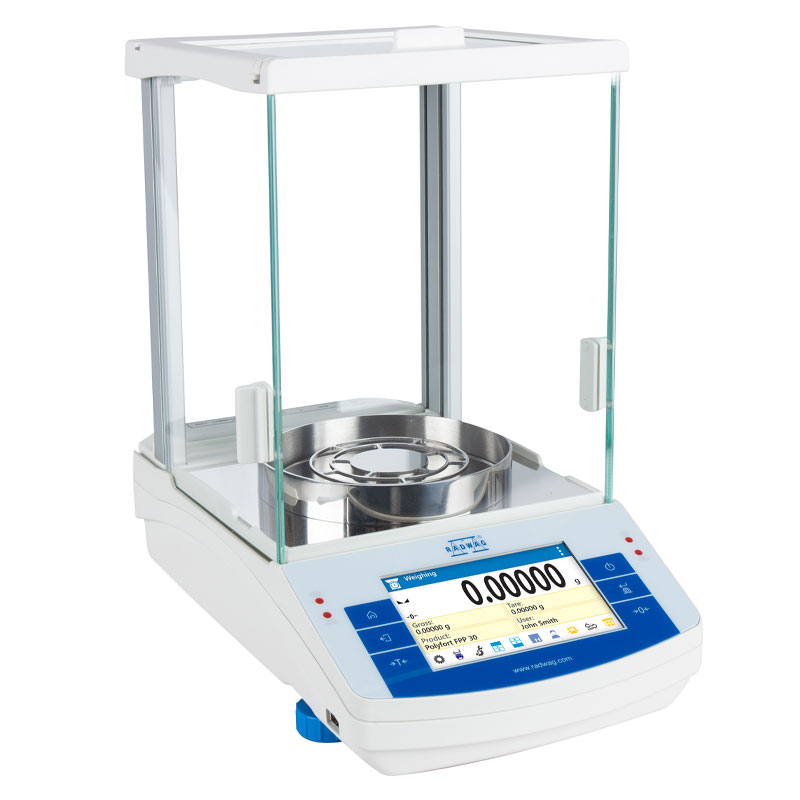

Bilancia analitica AS 82/220.X2 PLUS

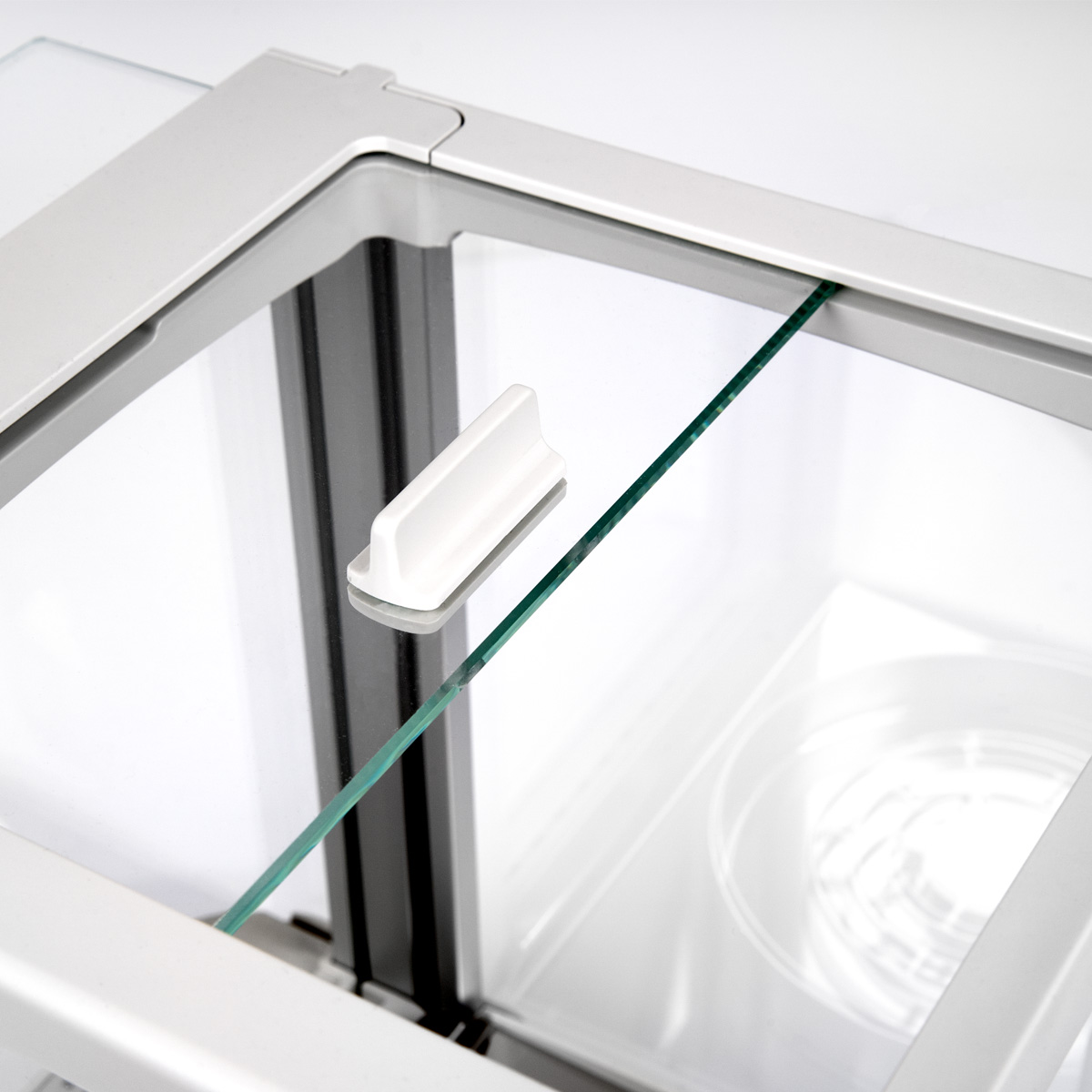

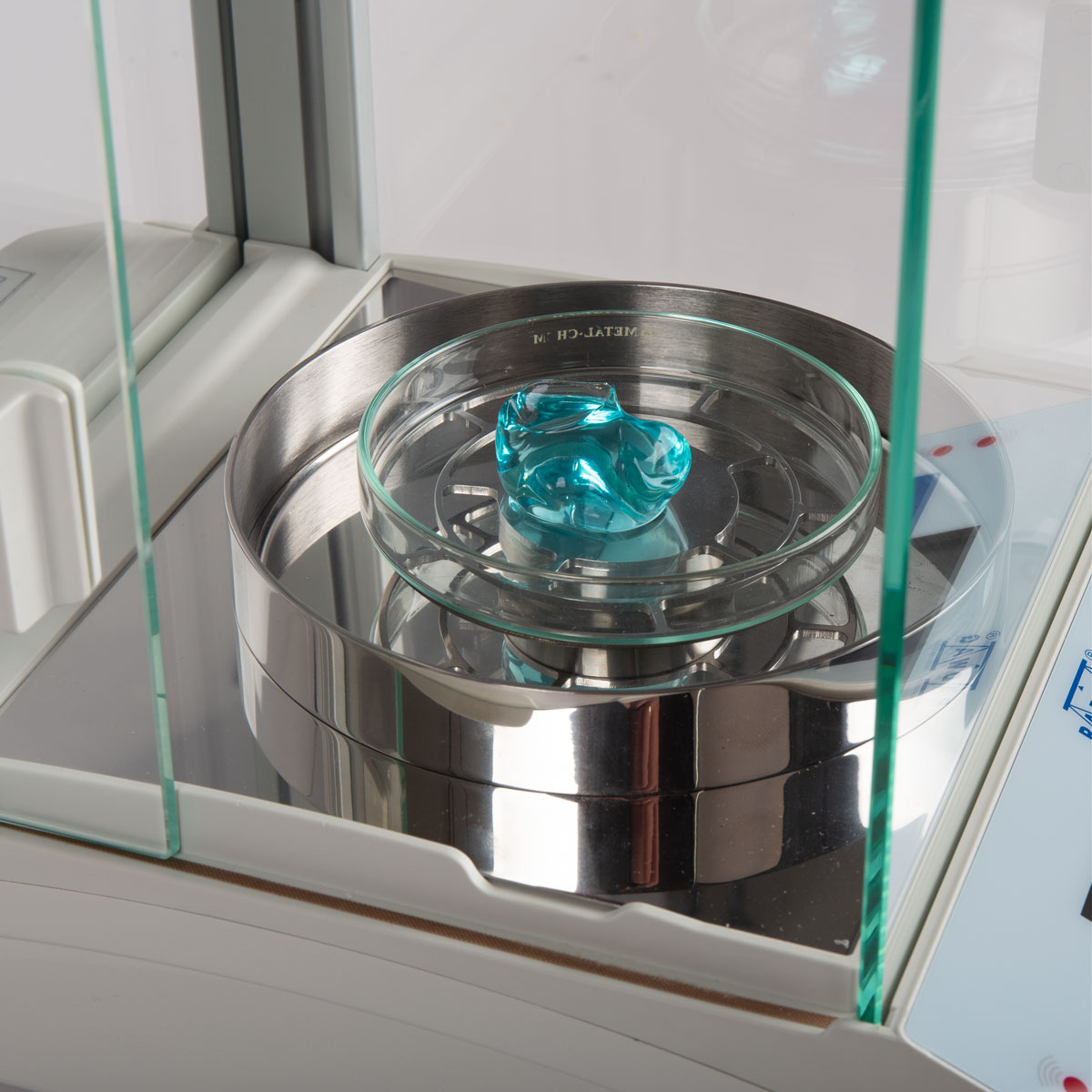

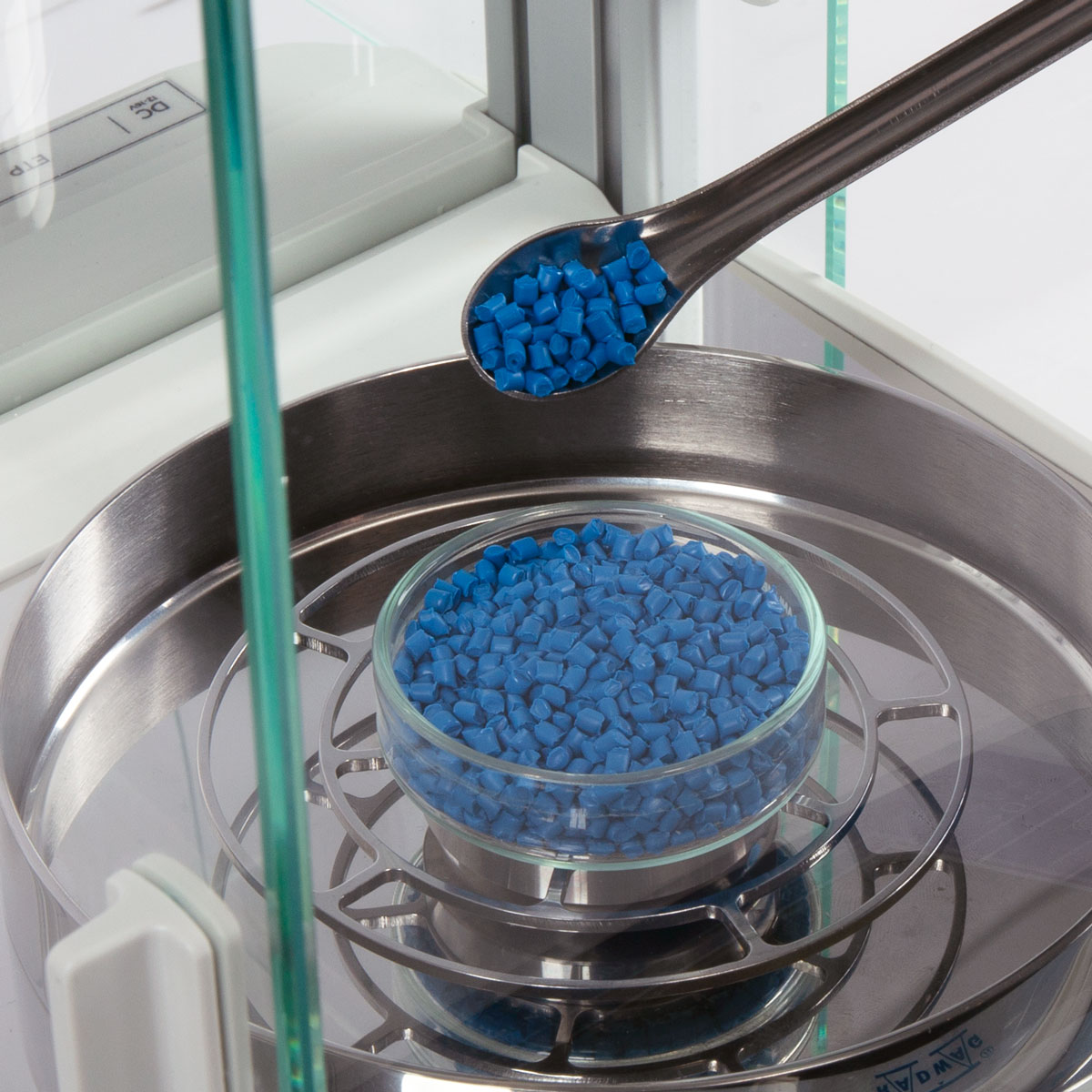

Nuovo design ergonomico

Pannello tattile a colori

Sistema di livellamento semiautomatico LevelSENSING

SMARTLab di RADWAG

Sensori

Il funzionamento senza contatto e i sensori programmabili riducono il numero di fasi della procedura di pesatura.

Memoria Alibi

La memoria interna di ALIBI garantisce la sicurezza e la continuità della raccolta dei dati per un lungo periodo di tempo, fino a 512.000 record di pesatura.

Wi-Fi®

Wi-Fi®Possibilità di utilizzare la bilancia in remoto da dispositivi Android, iOS e Windows.

Il livello di accesso ai dati dipende dai diritti degli utenti; l'amministratore può gestire fino a tre livelli di diritti.

Rapporti di pesatura automatici

I rapporti di processo e di sottopesata possono essere generati e inviati per l'archiviazione tramite USB a dispositivi esterni.

Monitoraggio delle condizioni ambientali

La collaborazione con il termoigrometro RADWAG consente di monitorare le condizioni ambientali come temperatura e umidità.

Database

• Prodotti (5 000 prodotti)

• Utenti (100 utenti)

• Imballaggi (100 imballaggi)

• Clienti (1 000 clienti)

• Ricette (100 ricette)

• Rapporti sulle ricette (500 rapporti)

• Condizioni ambientali (10 000 record)

• Pesatura (50 000 record)

• Memoria Alibi (512.000 record).

Interfacce di comunicazione

Learn about the use and maintenance of stainless steel products:

Stainless Steel in RADWAG products. Standard and special applications

Wi-Fi® is a registered trademark of Wi-Fi Alliance®.

Additional fee

Additional fee

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Português (Brasil)

Português (Brasil) Deutsch

Deutsch English

English Español

Español Français

Français Japanese (日本語)

Japanese (日本語) Polski

Polski Türkiye

Türkiye Česky

Česky 中文

中文